Solución de fábrica inalámbrica de Huawei para fabricación

Safety is the solid foundation of an enterprise's reliability, the basic requirement for an enterprise's sustainable development, and the most important way to maintain an enterprise's competitiveness. Strengthening safety management and enhancing safety level is the key to enterprise survival and development. With the rapid development of China's economic construction, and diversified enterprise property rights and operation and management modes, the production safety situation becomes more complex, safety data increases dramatically, especially in high-risk environments, remote areas, and safety monitoring situation of mobile medium becomes increasingly prominent. Meanwhile, production safety of the manufacturing industry faces more challenges caused by safety problems, such as personal safety, material safety, equipment safety, productivity, quality safety, and destruction of the nature and environment.

Preface

Safety is the solid foundation of an enterprise's reliability, the basic requirement for an enterprise's sustainable development, and the most important way to maintain an enterprise's competitiveness. Strengthening safety management and enhancing safety level is the key to enterprise survival and development. With the rapid development of China's economic construction, and diversified enterprise property rights and operation and management modes, the production safety situation becomes more complex, safety data increases dramatically, especially in high-risk environments, remote areas, and safety monitoring situation of mobile medium becomes increasingly prominent. Meanwhile, production safety of the manufacturing industry faces more challenges caused by safety problems, such as personal safety, material safety, equipment safety, productivity, quality safety, and destruction of the nature and environment.

Traditionally, wired networks are used to ensure the production safety of the manufacturing industry. On such networks, fiber optic cables are used to achieve safety monitoring and dispatching. At the same time, operators' 3G wireless networks serve as a supplement. However, remote and high-risk areas are hard for wired networks to cover, and operators' 3G networks have coverage holes, low transmission reliability, and low bandwidth. Therefore, using an LTE network that is dedicated for production and supplemented with Wi-Fi coverage in hotspots as the safety monitoring wireless network can help establish an efficient, quick, and reliable information system, get dynamic state of production safety in time, improve production safety supervision, management information level, and efficiency to ensure enterprises' safe production.

Challenges

The manufacturing industry faces the following problems in its safety monitoring and dispatching:

- Video monitoring does not cover all areas of factories and material safety cannot be guaranteed. Large manufacturers, such as steel factories, have many yards, warehouses, and logistics places that are far away from the main factory area. Fiber optic cables cannot be deployed in these areas. In order to ensure the safety of these places, operators' 3G networks must be used to carry out real-time monitoring. However, these 3G networks provide unstable and poor video transmission.

- Monitoring of environment and energy medium is difficult and environment safety cannot be guaranteed. The manufacturing industry has high energy consumption and emission. Therefore, monitoring of gas usage, sewerage, drainage and gas emissions is particularly important. There are a number of monitoring points in a factory and many of the monitoring points are usually in hazardous areas or far away from the main factory area. As a result, wired networks require high costs or even cannot be deployed. When using operators' 3G networks, capacity from multiple monitoring points is large and concurrent data transmission is unreliable, resulting in untimely delivery of monitoring information to the monitoring center.

- Inefficient manual preventive maintenance leaves risks in equipment safety. Equipment preventive maintenance is a routine in the manufacturing industry to exclude accidents and predict equipment performance. Traditional manual preventive maintenance inspection information is recorded in hard copies, including the task assignment and standard. This method is inconvenient and prone to errors. During working, information cannot be queried and input in a timely manner. In addition, ineffective personnel supervision often causes intentional or unintentional omission, inefficient inspection, and untimely exclusion of accidents.

- Personnel enter hazardous areas by mistake and their lives are under threat. Large manufacturers, such as steel factories, have many high-temperature, toxic, and high-voltage areas. Although these areas have warning signs, onsite operators often enter these hazardous areas by mistake due to misoperations and warnings are not received in time, which may cause human injuries.

- Vehicle management is difficult and dispatching is not timely. In the manufacturing industry, most factories are built on a vast area. Enterprises often use GPS positioning and 3G network transmission to manage and dispatch vehicles and perform tracking monitoring. Since the factories are usually located in remote areas, many places have weak 3G signals or even no signal. Therefore, unstable data transmission, inaccurate positioning, and untimely transmission of dispatching information occur.

- Untimely fault diagnosis leads to low production efficiency. Large manufacturers, such as large-scale steel factories, usually have a number of factories that are distributed in many different regions. Onsite equipment maintenance personnel have limited experience and expert resources are insufficient. If sudden faults occur, experts from headquarters are required to provide onsite support, resulting in untimely equipment diagnosis. Consequently, the production efficiency is greatly affected.

All the preceding problems and challenges are caused by the lack of enterprise wireless networks or poor performance of wireless networks. Therefore, deploying a dedicated wireless network that features a high bandwidth, wide coverage, short delay and provides diversified services such as HD video, big data, and voice services is the only way for enterprises to solve and meet the preceding problems and challenges.

Huawei Wireless Factory Solution for Manufacturing

Overview

Huawei eLTE broadband wireless network consists of the eCNS600 small core network and DBS3900 distributed base station, and features small size, light weight, industrial performance, and easy installation and deployment. LTE broadband wireless network has a high bandwidth (downlink throughput: 100 Mbps, uplink throughput: 50 Mbps), wide coverage (exceeding 20 km2), high mobility (supporting a speed of 120 km/h), and supports concurrent big data transmission, HD video transmission, remote data collection, broadband trunking services. The LTE broadband wireless network can effectively achieve wide coverage of steel factories and ensures safety monitoring and real-time dispatching of steel production. Huawei WLAN wireless network supports flexible networking and a high bandwidth and can supplement the LTE to provide wireless coverage of applications and hotspots such as warehouse and offices, and achieve efficient and convenient production and office operation.

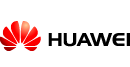

To help manufacturing customers deal with safety monitoring and dispatching challenges, Huawei provides an LTE + Wi-Fi-based IP bearer network for production and office on the basis of eLTE broadband wireless network and leading Wi-Fi solutions and products. This LTE+ Wi-Fi-based network not only solves safety monitoring and dispatching problems but also provides Wi-Fi in office buildings to support office work. By using characteristics of LTE and Wi-Fi, this solution enables LTE to bear vehicle logistics management, environment and energy medium test, factory monitoring, equipment spot-check, Wi-Fi to position staff for their safety and provide a mobile office network, and LTE or Wi-Fi to flexibly bear remote equipment fault diagnosis depending on site requirements. This solution helps manufacturing customers achieve effective production safety monitoring and dispatching, improve production safety, and significantly improve production and office operation efficiency.

Figure 1 Overview of Huawei wireless factory solution for manufacturing

Highlights

LTE bears remote video monitoring, multimedia trunking, dispatching, and production environment monitoring.

- Wide coverage: A 100-km remote LTE network provides seamless network coverage of 20 m2.

- High bandwidth: The downlink and uplink bandwidths are 100 Mbps and 50 Mbps, respectively. The high bandwidth can satisfy requirements of large production data transmission.

- LTE multimedia trunking visualizes safety production dispatching.

Wi-Fi bears mobile office, material positioning.

- Accurate positioning: The positioning accuracy is 3 m and production alarm information is sent in advance.

Application scenarios

1 LTE environment and energy medium monitoring, video surveillance

— a real-time remote monitoring platform

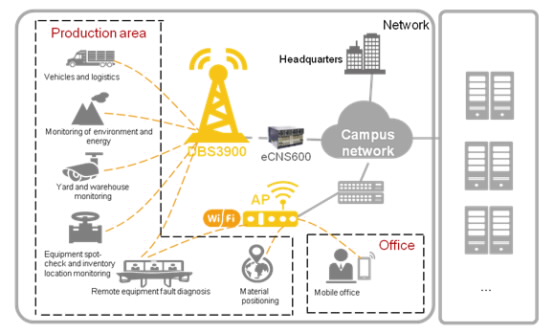

This solution uses LTE as the transmission channel for the environment and energy medium monitoring, HD video surveillance ,which effectively monitors gas usage, sewerage, drainage and gas emissions in dangerous and remote areas of factories. In this solution, the RTUs and CPEs are installed at monitoring points. The RTUs receive data using the serial bus and access the network using the CPEs. In this way, the monitoring points and the monitoring platform achieve data interaction and real-time control of energy use and pollution emissions. Based on monitoring data, the monitoring center can adjust the energy use or pollution control strategies in real time.

Figure 2 LTE environment and energy medium monitoring solution

2LTE factory vehicle and logistics monitoring — a real-time monitoring and dispatching platform for vehicle and logistics

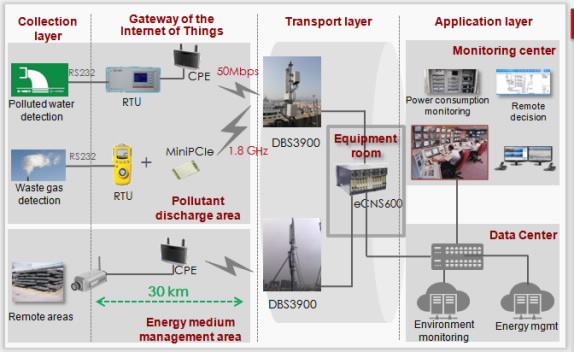

This solution uses GPS, excellent mobile performance of the LTE network (120 km/h and 30 Mbps), a vehicle-mounted smart terminal, and a camera inside the vehicle (with built-in Mini PCIe LTE wireless module). The vehicle-mounted smart terminal uses the LTE network to interact with the vehicle dispatching monitoring platform. The camera inside the vehicle uses the LTE network to upload real-time videos. The monitoring center can show the vehicle track and route in the factory, and monitors and dispatches the vehicle route.

Figure 3 LTE factory vehicle logistics monitoring solution

3remote equipment fault diagnosis — fast, accurate, and efficient remote equipment diagnosis

HD telepresence, convergent conference, and wireless video monitoring are successfully used in enterprise remote equipment fault diagnosis. The onsite mobile wireless camera can achieve multi-angle shooting of the fault equipment. The LTE network or Wi-Fi enables HD video transmission of HD images of the fault equipment. Onsite staff use mobile PADs to interact with the telepresence conference of the background expert system, which enables onsite maintenance personnel to communicate timely with experts at the headquarter. Therefore, remote equipment fault diagnosis is achieved, which not only reduces expert travel expenses but solves all kinds of problems. The 1080P HD video can fully meet the needs of remote expert diagnosis.

Figure 4 Remote equipment fault diagnosis solution

4Wi-Fi-based material positioning — ensuring material safety

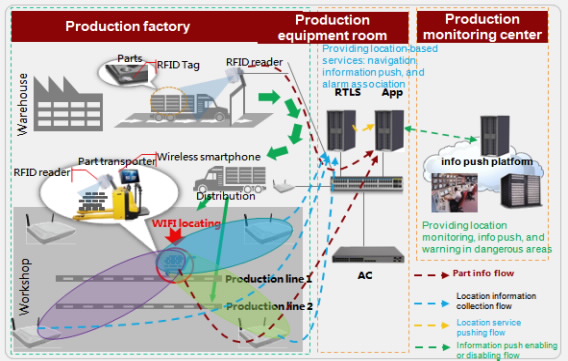

This solution provides material positioning services based on Wi-Fi product technology, RTLS positioning services, and smart terminals. When material are approaching or have entered dangerous areas, the monitoring platform sends real-time navigation and alarm information to effectively guarantee the personnel safety and lives.

Figure 5 Wi-Fi-based material positioning solutions

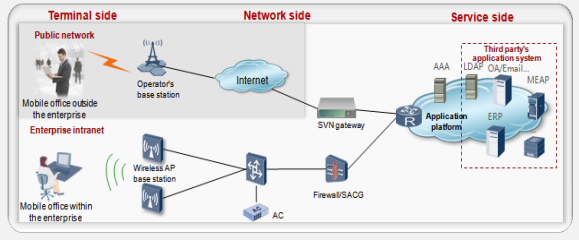

5Smart mobile office — boosting rapid development of enterprise businesses

This solution is based on Wi-Fi office network and provides safe mobile office environment for the manufacturing industry. In the industry, Huawei is the only one that provides a comprehensive set of one-stop mobile office components (cloud, pipe, and terminal) and the open software development kit (SDK), which can perfectly integrate with enterprise applications. Huawei's automatic perception, seamless mobility, and intelligent access are based on the same authentication policy, improving office convenience and safety, enabling leaders to approve things to be done and personnel to receive and send emails timely, and improving personnel efficiency and satisfaction.

Figure 6 Mobile office solutions

Customer Benefits

Huawei wireless factory solution for manufacturing uses LTE broadband wireless network and Wi-Fi hotspot coverage to effectively improve the safe production management level and office efficiency of the manufacturing industry, achieve 7x24-hour monitoring, and help boost enterprise businesses.

Agile manufacturing uses wireless networks to improve production safety.

- Personnel safety: Effective personnel positioning and advance notification of onsite personnel dangers guarantee personnel safety and lives.

- Material safety: Remote yards, warehouses, and logistic areas are effectively monitored to prevent material from being stolen.

- Environment safety: Gas usage, sewerage, drainage, and gas emissions are monitored to get real-time sewerage and energy consumption information of enterprises, flexibly develop pollution control and energy-saving policies, ensure environmental safety, and build green manufacturing.

- Equipment safety: Equipment risks are timely troubleshot and problems are solved to ensure safe and stable operation of equipment.

Mobile production and office enhance operating efficiency for enterprises.

Mobile production and office greatly improve working efficiency.