The Huawei Digital Oil and Gas Production Solution supports networks, communications, and security services based on careful analysis of the unique communications needs of oil and gas companies. In order to provide the industry with the most robust, yet flexible, solutions Huawei has carefully studied the numerous challenges the industry faces and identified some key challenges:

- Globally dispersed sites make unified communications difficult

- Emergency communications are fragmented and not interoperable

- Current solution options don’t fit the varied environments oil and gas fields operate in

- Security, both for employees and assets, is difficult to oversee

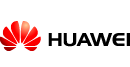

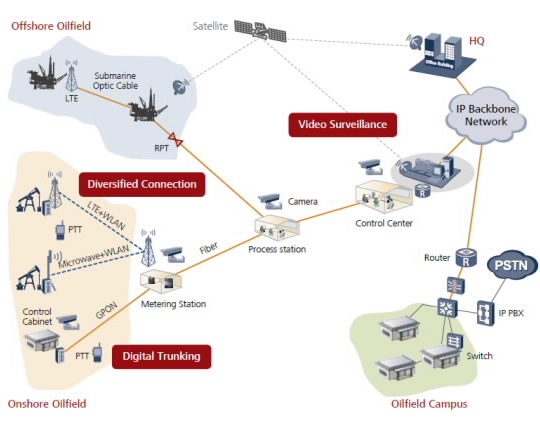

Because the production environment of every oil or gas field is unique, the Huawei Digital Oil and Gas Production Solution provides multiple carrier networks (including LTE, WLAN, xPON, microwave and cabling) to ensure 100% coverage of oilfield production automation. No other vendor can offer this variety of products and solutions.

Digital Oil and Gas Production Solution Overview

The solution can be further broken down into five key components: LTE + WLAN Networks, Remote Well Networks, New Oil and Gas field (xPON) Networks, Multimedia Digital Trunking Communications, and Video Surveillance.

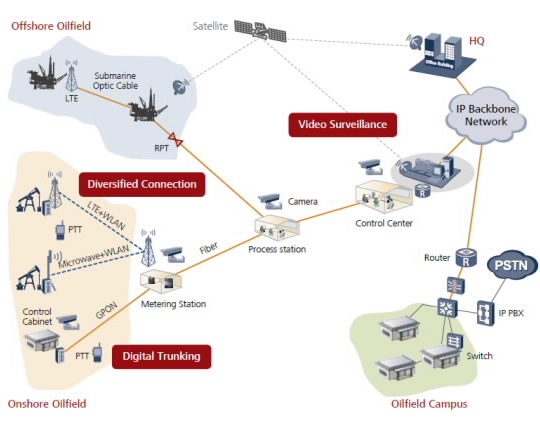

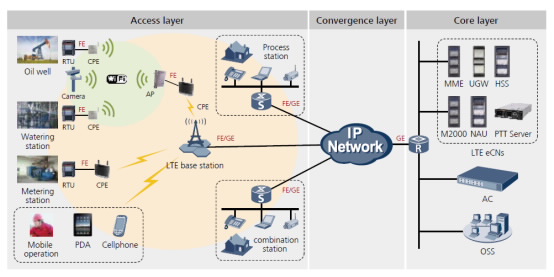

LTE + WLAN Network Solution

Designed especially for oil and gas wells spread across a large area, the Huawei LTE + WLAN solution provides an LTE network that is compatible with multiple terminals, providing comprehensive wireless coverage and service access for the area. LTE base-stations relay production and surveillance data via microwave or optical fibers to any fixed-line or mobile user within the coverage area of the LTE network. The data is also transmitted to enterprise networks using customer premise equipment (CPE). To support a broader network footprint, a WLAN network is deployed as a complement for the areas or production offices beyond the LTE network area. By combining an LTE with WLAN companies have access to a heterogeneous wireless solution that is capable of delivering voice, data, and video service over the same network.

LTE + WLAN Network Solution Overview

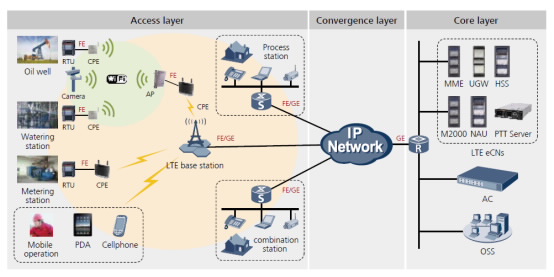

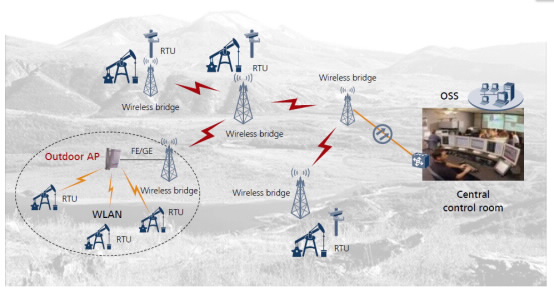

Small-scale Oilfield Network Solution

For remote areas that have a small number of wells, Huawei has developed a wireless transmission and coverage solution that links microwave equipment or wireless bridge to a WLAN network. The microwave equipment or wireless bridge transmits data between base stations and wells while the WLAN is deployed in smaller areas to provide signal coverage. This is much more cost-effective than laying out optical cables or building large numbers of wireless base-stations.

Microwave links have extremely high bandwidth that can be flexibly deployed while delivering reliable data transmission in any weather conditions. For small-scale operation sites, WLAN network coverage delivers flexible and reliable point-to-point or point-to-multipoint data transmissions. This combination of microwave or wireless bridge and WLAN provides the best, and most cost-effective, communications system available.

Small-scale Oilfield Network Solution Overview

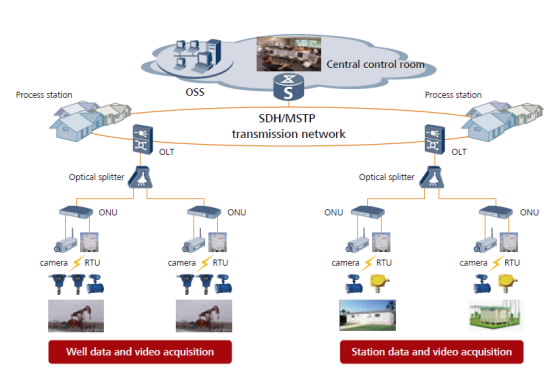

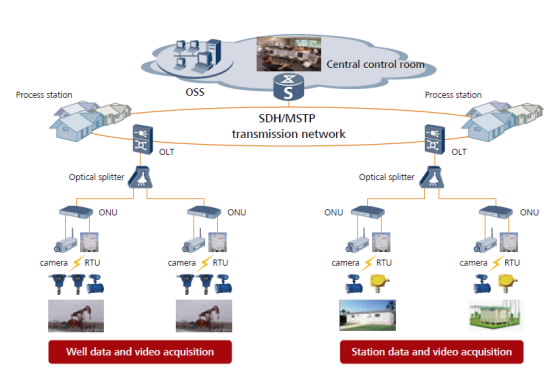

New Oil and Gas Field (xPON Network) Solution

Huawei created the xPON solution for new, mass-production oilfields. By laying optical cables alongside power cables to the surrounding areas of wells they are easy to service and provide wired transmission and access to communications services rapidly.

To implement this solution, a multi-service transmission platform (MSTP) ring network is built by laying optical fiber at the metering stations and processing stations and equipping these stations with an optical line terminal (OLT) to manage optical cable access. The OLT then run through optical fiber splitters, using the Passive Optical Network (PON), which allows connections to all wells. As an added advantage, splitting the optical power in passive mode saves energy.

An optical network unit (or ONU) is then deployed for individual or multiple oil wells. ONUs are plug and play devices that can be configured automatically and provide downlink to the field remote terminal unit (RTU) via optical fiber or network cables. With this deployment, operators in a central control room have access to field production data and live video returns.

New Oil and Gas Field (xPON Network) Solution Overview

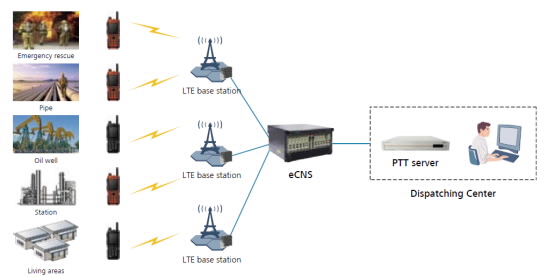

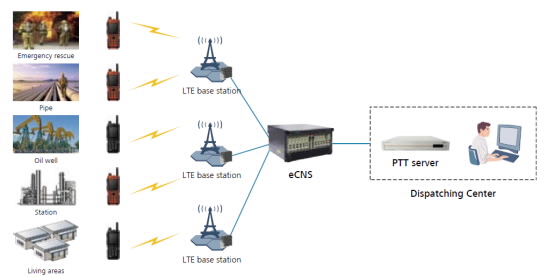

Multimedia Digital Trunking Communications Solution

The Huawei-designed wireless-network-based digital trunking communications system for oilfields helps manage scenarios like emergency rescues, pipeline preventive maintenance, field operations at oil wells and stations, and security patrolling of residential areas. The system enables users to enjoy cluster communications functions such as group calls, broadcast calls, dispatching, call control, and floor control.

By combining voice, data, and video services into one, users can see site conditions in real time. Site images and technical documentation can also be shared for easier troubleshooting and preventative maintenance. To ensure production safety, the user terminals have water-, shock-, dust-, and explosion-proof features.

Multimedia Digital Trunking Communications Overview

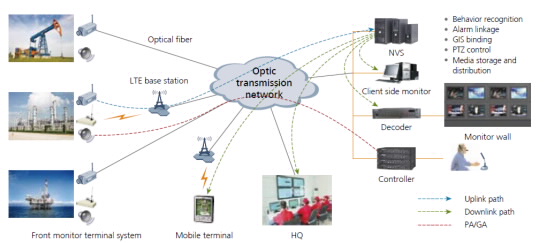

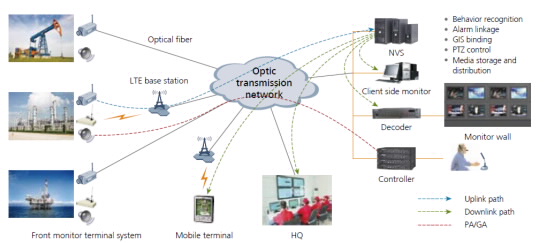

Video Surveillance Solution For Oil and Gas Production

Remote locations and difficult terrain can be overcome in the blink of any eye with the Huawei video surveillance solution for oil and gas companies. Pipelines, production centers, oilfields, and even surrounding areas are connected via cameras. These cameras monitor site conditions in real time and then intelligently analyze the images for intrusions or thefts.

Once an illegal intrusion is sensed, the system automatically sets off an alarm and reports the information to field personnel via the wireless network. The video surveillance system is also connected to a network that transfers the collected video data to a control center that can send a warning through the industrial broadcasting system to the intruders. These joint efforts ensure prompt handling of intrusion incidents and help guarantee safe production.

Video Surveillance Solution For Oil and Gas Production

Combined communications solutions help enterprises overcome any geographic hurdles.

- Save money by combining voice, data, and video services into one network

- Connect remote areas using a flexible solution that goes everywhere oil and gas flows

- Maintain contact no matter the terrain or weather conditions

- Access detailed site information in real time to prevent accidents

- Improve efficiency by viewing on-site information remotely during preventive maintenance and repairs

- Avoid production stoppages or property damage with integrated intrusion detection and alarm systems that enable personnel to promptly detect and handle incidents

Contact a Huawei Partner for Oil and Gas Production Infrastructure Solutions, or Email Us for more information.